Vol. 150, No. 26 — December 28, 2016

Registration

SOR/2016-311 December 9, 2016

ENERGY EFFICIENCY ACT

Energy Efficiency Regulations, 2016

P.C. 2016-1111 December 9, 2016

Whereas, pursuant to section 26 of the Energy Efficiency Act (see footnote a), a copy of the proposed Energy Efficiency Regulations, 2016, substantially in the annexed form, was published in the Canada Gazette, Part I, on April 30, 2016;

Therefore, His Excellency the Governor General in Council, on the recommendation of the Minister of Natural Resources, pursuant to sections 20 (see footnote b) and 25 of the Energy Efficiency Act (see footnote c), makes the annexed Energy Efficiency Regulations, 2016.

TABLE OF PROVISIONS

Energy Efficiency Regulations, 2016

Interpretation

1 Definitions

PART 1

General

Interpretation

2 Definitions

3 Incorporated products

Verification Mark

4 Verification mark

Provision of Information

5 Prescribed information

6 CFL life information

Information Pertaining to Imports

7 Prescribed information

Exemptions from Certain Provisions of the Act

8 Exemption — product to be modified

9 Exemption — incorporation into product for export

10 Exemption — product to be exported

11 Exemption — motors with same unique motor identifier

PART 2

Energy-Using Products

DIVISION 1

Household Appliances

Interpretation

12 Definitions

Labelling

13 EnerGuide label

14 Paper — adhesive and flap tags

15 Paper — hang tags

SUBDIVISION A

Clothes Dryers

16 Definition of clothes dryer

17 Size category

18 Energy-using product

19 Energy efficiency standards

20 Information

SUBDIVISION B

Clothes Washers

21 Definition of clothes washer

22 Size category

23 Energy-using product

24 Energy efficiency standards

25 Information

SUBDIVISION C

Integrated Clothes Washer-Dryers

26 Definitions

27 Size category — other than combination clothes washer-dryer

28 Type

29 Energy-using product

30 Energy efficiency standards

31 Information

SUBDIVISION D

Dishwashers

32 Definitions

33 Size category

34 Type

35 Labelling — total annual energy consumption

36 Energy-using product

37 Energy efficiency standards

38 Information

SUBDIVISION E

Refrigerators and Combination Refrigerator-Freezers

39 Definitions

40 Size category

41 Type

42 Energy-using products

43 Energy efficiency standards

44 Information

SUBDIVISION F

Freezers

45 Definitions

46 Size category

47 Type

48 Energy-using product

49 Energy efficiency standards

50 Information

SUBDIVISION G

Electric Ranges

51 Definitions

52 Size category

53 Type

54 Energy-using product

55 Energy efficiency standards

56 Information

SUBDIVISION H

Gas Ranges

57 Definition of gas range

58 Energy-using product

59 Energy efficiency standard

60 Information

SUBDIVISION I

Dehumidifiers

61 Definitions

62 Energy-using product

63 Energy efficiency standards

64 Information

DIVISION 2

Air Conditioners, Condensing Units and Chillers

Interpretation

107 Definitions

SUBDIVISION A

Room Air Conditioners

108 Definitions

109 Type

110 Cooling capacity category

111 Energy-using product

112 Energy efficiency standards

113 Information

114 Form of labelling

115 Manner of labelling

SUBDIVISION B

Large Air Conditioners

116 Definitions

117 Energy-using product

118 Energy efficiency standards — cooled by air

119 Information

SUBDIVISION C

Packaged Terminal Air Conditioners

120 Definitions

121 Energy-using product

122 Energy efficiency standards

123 Information

SUBDIVISION D

Single Package Central Air Conditioners

124 Definitions

125 Energy-using product

126 Energy efficiency standards

127 Information

SUBDIVISION E

Single Package Vertical Air Conditioners

128 Definition of single package vertical air conditioner

129 Energy-using product

130 Energy efficiency standards

131 Information

SUBDIVISION F

Split-System Central Air Conditioners

132 Definition of split-system central air conditioner

133 Energy-using product

134 Energy efficiency standards

135 Information

SUBDIVISION G

Large Condensing Units

136 Definition of large condensing unit

137 Energy-using product

138 Energy efficiency standards

139 Information

SUBDIVISION H

Chillers

140 Definitions

141 Energy-using product

142 Energy efficiency standards

143 Information

DIVISION 3

Heat Pumps

Interpretation

186 Definitions

SUBDIVISION A

Ground-Source Heat Pumps

187 Definitions

188 Energy-using product

189 Energy efficiency standards

190 Information

SUBDIVISION B

Internal Water Loop Heat Pumps

191 Definition of internal water loop heat pump

192 Energy-using product

193 Energy efficiency standards

194 Information

SUBDIVISION C

Large Heat Pumps

195 Definitions

196 Energy-using product

197 Energy efficiency standards

198 Information

SUBDIVISION D

Packaged Terminal Heat Pumps

199 Definitions

200 Energy-using product

201 Energy efficiency standards

202 Information

SUBDIVISION E

Single Package Heat Pumps

203 Definitions

204 Energy-using product

205 Energy efficiency standards

206 Information

SUBDIVISION F

Single Package Vertical Heat Pumps

207 Definition of single package vertical heat pump

208 Energy-using product

209 Energy efficiency standards

210 Information

SUBDIVISION G

Split-System Heat Pumps

211 Definition of split-system heat pump

212 Energy-using product

213 Energy efficiency standards

214 Information

DIVISION 4

Furnaces, Fireplaces and Unit Heaters

SUBDIVISION A

Gas Furnaces

257 Definitions

258 Energy-using product

259 Energy efficiency standards

260 Information

SUBDIVISION B

Oil-Fired Furnaces

261 Definitions

262 Energy-using product

263 Energy efficiency standard

264 Information

SUBDIVISION C

Gas Fireplaces

265 Definitions

266 Energy-using product

267 Information

SUBDIVISION D

Gas-Fired Unit Heaters

268 Definitions

269 Energy-using product

270 Energy efficiency standards

271 Information

DIVISION 5

Boilers

Interpretation

314 Definitions

SUBDIVISION A

Gas Boilers

315 Definitions

316 Energy-using product

317 Energy efficiency standards

318 Information

SUBDIVISION B

Oil-Fired Boilers

319 Definitions

320 Energy-using product

321 Energy efficiency standards

322 Information

SUBDIVISION C

Electric Boilers

323 Definition of electric boiler

324 Energy-using product

325 Energy efficiency standard

326 Information

DIVISION 6

Water Heaters

Interpretation

369 Definition of Vr

SUBDIVISION A

Electric Water Heaters

370 Definitions

371 Energy-using product

372 Energy efficiency standards

373 Information

SUBDIVISION B

Gas-Fired Storage Water Heaters

374 Definitions

375 Energy-using product

376 Energy efficiency standards

377 Information

SUBDIVISION C

Oil-Fired Water Heaters

378 Definitions

379 Energy-using product

380 Energy efficiency standards

381 Information

DIVISION 7

Lamps and Lamp Ballasts

Interpretation

424 Definitions

Labelling

425 Label required

426 Information on principal display panel

427 Value of CFL life

428 Design voltage other than 120 V

429 Multiple lamps in common package

SUBDIVISION A

Compact Fluorescent Lamps

430 Definitions

431 Energy-using product

432 Information

SUBDIVISION B

General Service Lamps

433 Definition of general service lamp

434 Energy-using product

435 Energy efficiency standards

436 Information

SUBDIVISION C

Modified Spectrum Incandescent Lamps

437 Definition of modified spectrum incandescent lamp

438 Energy-using product

439 Energy efficiency standards

440 Information

SUBDIVISION D

General Service Incandescent Reflector Lamps

441 Definitions

442 Energy-using product

443 Energy efficiency standards

444 Information

SUBDIVISION E

General Service Fluorescent Lamps

445 Definitions

446 Energy-using product

447 Energy efficiency standards

448 Information

SUBDIVISION F

Fluorescent Lamp Ballasts

449 Definitions

450 Energy-using product

451 Energy efficiency standards

452 Information

DIVISION 8

Lighting Fixtures

Interpretation

506 Definitions

SUBDIVISION A

Torchieres

507 Definitions

508 Energy-using product

509 Energy efficiency standards

510 Information

SUBDIVISION B

Ceiling Fans

511 Definition of ceiling fan

512 Energy-using product

513 Energy efficiency standard

514 Information

SUBDIVISION C

Ceiling Fan Light Kits

515 Definition of ceiling fan light kit

516 Energy-using product

517 Energy efficiency standard

518 Information

SUBDIVISION D

Exit Signs

519 Definitions

520 Energy-using product

521 Energy efficiency standards

522 Information

SUBDIVISION E

Traffic Signal Modules

523 Definitions

524 Energy-using product

525 Energy efficiency standards

526 Information

SUBDIVISION F

Pedestrian Modules

527 Definitions

528 Energy-using product

529 Energy efficiency standards

530 Information

DIVISION 9

Electronic Products

Interpretation

573 Definitions

SUBDIVISION A

Compact Audio Products

574 Definitions

575 Energy-using product

576 Energy efficiency standards

577 Information

SUBDIVISION B

Video Products

578 Definitions

579 Energy-using product

580 Energy efficiency standards

581 Information

SUBDIVISION C

Televisions

582 Definitions

583 Energy-using product

584 Energy efficiency standards

585 Information

SUBDIVISION D

External Power Supplies

586 Definitions

587 Energy-using product

588 Energy efficiency standard

589 Information

DIVISION 10

Commercial Refrigeration

Interpretation

635 Definition of Edaily

SUBDIVISION A

Commercial Refrigerators, Refrigerator-Freezers and Freezers

636 Definitions

Commercial Refrigerators

637 Energy-using product

638 Energy efficiency standards

639 Information

Commercial Refrigerator-Freezers

640 Energy-using product

641 Energy efficiency standards

642 Information

Commercial Freezers

643 Energy-using product

644 Energy efficiency standards

645 Information

SUBDIVISION B

Refrigerated Vending Machines

646 Definitions

Refrigerated Beverage Vending Machines

647 Energy-using product

648 Energy efficiency standards

649 Information

Snack and Refrigerated Beverage Vending Machines

650 Energy-using product

651 Energy efficiency standards

652 Information

SUBDIVISION C

Ice-Makers

653 Definitions

654 Energy-using product

655 Energy efficiency standards

656 Information

DIVISION 11

Dry-type Transformers

703 Definitions

704 Energy-using product

705 Energy efficiency standards

706 Information

DIVISION 12

Motors

749 Definitions

750 Energy-using product

751 Energy efficiency standards

752 Information

796 Repeal

Coming into Force

797 Six months after publication

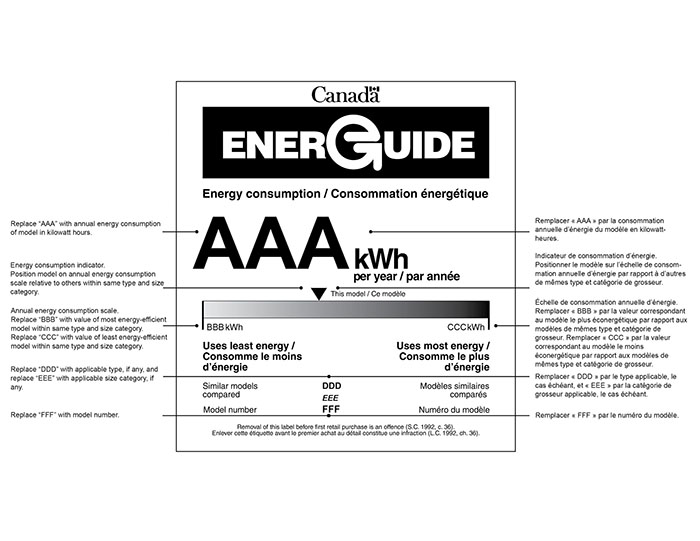

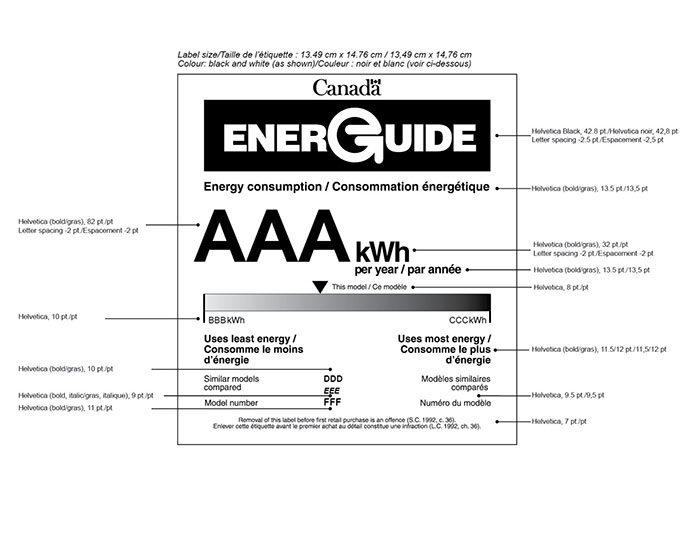

SCHEDULE 1

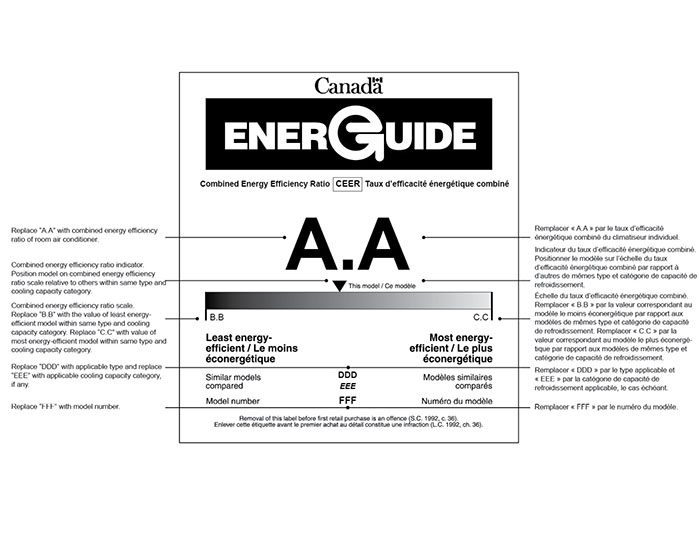

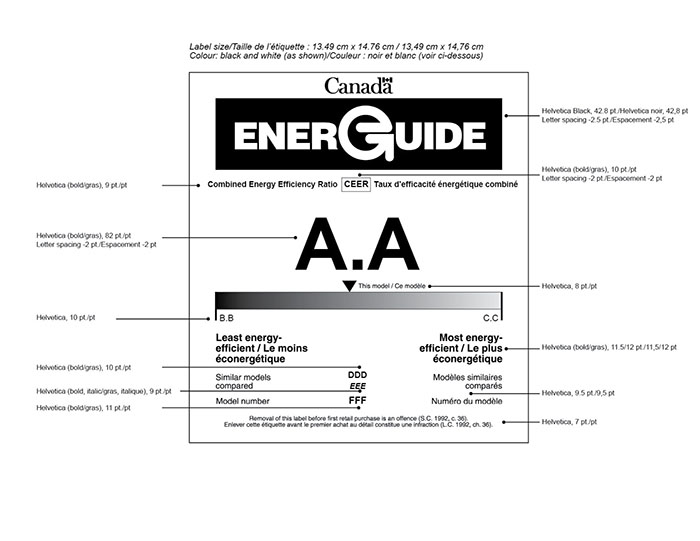

Explanation for Elements on Household Appliance Energy Efficiency Label

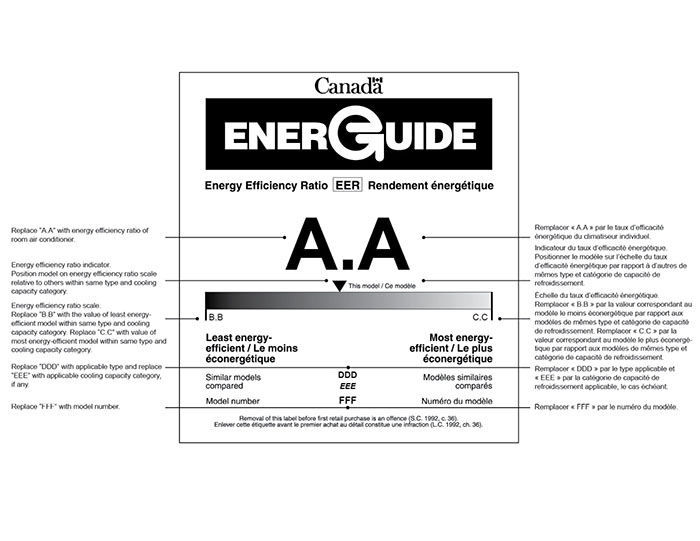

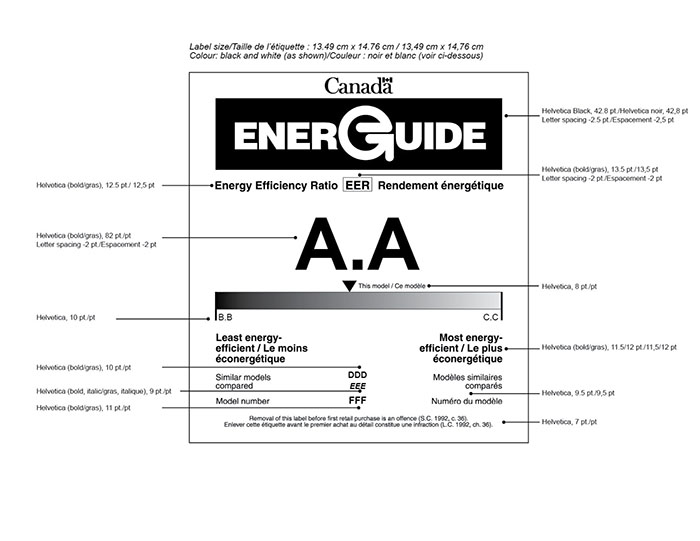

SCHEDULE 2

Explanation for Elements on Room Air Conditioner Energy Efficiency Label

SCHEDULE 3

Explanation for Elements on Room Air Conditioner Energy Efficiency Label

Energy Efficiency Regulations, 2016

Interpretation

Definitions

1 (1) The following definitions apply in these Regulations.

Act means the Energy Efficiency Act. (Loi)

adhesive tag means a label that is attached to an energy-using product by at least two strips of adhesive that are located on opposite edges of the label. (étiquette adhésive)

AHRI means the Air-Conditioning, Heating and Refrigeration Institute. (AHRI)

ANSI means the American National Standards Institute. (ANSI)

ASHRAE means the American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE)

CGA means the Canadian Gas Association. (ACG)

CIE means the International Commission on Illumination. (CIE)

CSA means the Canadian Standards Association. (CSA)

flap tag means a label whose top edge is attached to an energy-using product by one strip of adhesive. (vignette)

hang tag means a label that is attached to an energy-using product by material that is looped around a section of the product so that the label hangs freely from the product. (étiquette volante)

household means manufactured or sold primarily for use in a dwelling. (domestique)

IEC means the International Electrotechnical Commission. (CEI)

IEEE means the Institute of Electrical and Electronics Engineers. (IEEE)

IES means the Illuminating Engineering Society of North America. (IES)

mains power means an alternating current electric power source that is in a building and is less than or equal to a nominal 240-volt single-phase supply. (alimentation principale)

model number means, in respect of any model of an energy-using product, the designator that is assigned to that model for the purposes of these Regulations and that distinguishes it from similar models. (numéro de modèle)

NEMA means the National Electrical Manufacturers Association. (NEMA)

unique motor identifier means an identifier consisting of the information set out below, in the following sequence:

- (a) the name of the manufacturer, in abbreviated form;

- (b) the nominal power of the motor, expressed in kilowatts for an IEC design motor or in horsepower for a NEMA design motor;

- (c) the number of poles; and

- (d) a statement as to whether the motor is of open or enclosed construction. (identificateur unique du moteur)

Reference to energy-using product

(2) In these Regulations, a reference to an energy-using product is a reference to that product as defined in the Division or Subdivision associated with it.

Incorporated standards

(3) In these Regulations, a reference to an AHRI, ANSI, ASHRAE, CGA, CIE, CSA or IES standard is to be read as a reference to the standard as amended from time to time.

PART 1

General

Interpretation

Definitions

2 The following definitions apply in this Part.

certification body means, in respect of an energy-using product, a body that is accredited by the Standards Council of Canada to operate a certification program in respect of the energy efficiency of the product. (organisme de certification)

verification mark means, in respect of an energy-using product, a mark that is

- (a) issued by a certification body to signify that the body has

- (i) determined that the product complies with the applicable energy efficiency standard, and

- (ii) if the product is one for which information must be provided to the Minister for the purpose of subsection 5(1) of the Act, verified the information that is related to the product’s energy performance; or

- (b) issued by a province to signify that the product complies with the province’s energy efficiency standard. (marque de vérification)

Incorporated products

3 Unless otherwise specified by these Regulations, an energy-using product that is incorporated into another product remains an energy-using product for the purposes of these Regulations even if the other product is not an energy-using product.

Verification Mark

Verification mark

4 (1) Subject to subsections (3) to (5), every energy-using product that, for the purpose of sale or lease, is shipped from one province to another or imported into Canada must be labelled with a verification mark that is issued by

- (a) a certification body; or

- (b) a province whose energy efficiency standard for the product is equivalent to or exceeds the energy efficiency standard prescribed for the product in these Regulations.

Location and visibility

(2) The verification mark must be readily visible on the surface of the energy-using product. However, in respect of a CFL, general service lamp, modified spectrum incandescent lamp, general service fluorescent lamp or general service incandescent reflector lamp, the verification mark may be on the exterior of the product’s package.

Exception — CFL

(3) A CFL is not required to be labelled with a verification mark if

- (a) a laboratory that is accredited to test the energy performance of lighting products by either the Standards Council of Canada or the National Voluntary Laboratory Accreditation Program has verified the values for nominal power, luminous flux and correlated colour temperature provided to the Minister under subsection 439(1); and

- (b) a laboratory that is referred to in paragraph (a), an A2LA certified laboratory or an ISO 9000 certified laboratory or manufacturing facility has

- (i) if the life testing of the CFL is completed, verified the value for life provided to the Minister under subsection 439(1), or

- (ii) if the life testing of the CFL is not completed, verified 40% of its design life and at that point in the testing not more than one unit in the test sample has failed.

Exception — external power supplies

(4) An external power supply is not required to be labelled with a verification mark if

- (a) it is labelled with a mark in accordance with the U.S. Department of Energy publication entitled “International Efficiency Marking Protocol for External Power Supplies”, as amended from time to time;

- (b) a certification body has verified the information related to the product’s energy performance that is provided to the Minister for the purpose of subsection 5(1) of the Act; and

- (c) it is labelled with the same model number as that used when the information was verified.

Exception — general service lamps

(5) Until March 31, 2018, a general service lamp is not required to be labelled with a verification mark if a certification body

- (a) has determined that the lamp complies with the applicable energy efficiency standard; and

- (b) has verified the information related to the product’s energy performance that is provided to the Minister for the purpose of subsection 5(1) of the Act.

Provision of Information

Prescribed information

5 (1) A dealer who, for the purpose of sale or lease, ships an energy-using product from one province to another or imports an energy-using product into Canada must, for the purpose of subsection 5(1) of the Act, provide the following information to the Minister:

- (a) the name of the product as prescribed in these Regulations;

- (b) the brand name of the product, if any;

- (c) the product’s model number or, in the case of a motor, the product’s model number or unique motor identifier;

- (d) the name of the product’s manufacturer;

- (e) one of the following, namely,

- (i) the name of the certification body or province whose verification mark will be on the product or its package,

- (ii) in the case of a CFL, the name of the laboratory referred to in paragraph 4(3)(a) and the name of the laboratory or manufacturing facility referred to in paragraph 4(3)(b),

- (iii) in the case of an external power supply, the name of the certification body referred to in paragraph 4(4)(b), or

- (iv) in the case of a general service lamp or modified spectrum incandescent lamp for which there is no energy efficiency standard, if a laboratory that is accredited to test the energy performance of lighting products by either the Standards Council of Canada or the National Voluntary Laboratory Accreditation Program has verified the information displayed on the product’s package, the name of that laboratory; and

- (f) any other information that is prescribed in these Regulations to be provided to the Minister for the purpose of subsection 5(1) of the Act.

Manner and time

(2) The information must be provided electronically or by fax, hand delivery, courier or mail before the product is imported into Canada or shipped from one province to another.

CFL life information

6 (1) Despite paragraph 5(1)(f), a dealer is not required to provide information related to the life of a CFL if

- (a) at the time the information is to be provided the life testing of the product is not completed, but 40% of the product’s design life has been verified as described in subparagraph 4(3)(b)(ii); and

- (b) the dealer provides the following information to the Minister together with the information provided under subsection 5(1):

- (i) a statement indicating that 40% of the product’s design life has been verified,

- (ii) the date on which life testing began,

- (iii) the design life of the product, and

- (iv) the number of hours of life that have been verified.

Verified CFL life

(2) Within 30 days after the day on which the life testing of the CFL is completed, the dealer must provide the Minister with the following information:

- (a) the product’s life as verified; and

- (b) the name of the laboratory or manufacturing facility that performed the verification, if it is different from the name provided under subparagraph 5(1)(e)(ii).

Information Pertaining to Imports

Prescribed information

7 (1) A dealer who, for the purpose of sale or lease, imports an energy-using product into Canada must, for the purpose of subsection 5(1) of the Act, provide the following information to the Minister:

- (a) the name of the product as prescribed in these Regulations;

- (b) the brand name of the product, if any;

- (c) the product’s model number or, in the case of a motor, the product’s model number or unique motor identifier;

- (d) the dealer’s address; and

- (e) a statement as to whether the product is being imported

- (i) for sale or lease in Canada without modification,

- (ii) for sale or lease in Canada after being modified to comply with the applicable energy efficiency standard, or

- (iii) for incorporation into any other product that is to be exported from Canada.

Manner and time

(2) The information must be provided by including it in any customs invoice or commercial invoice that is required to be provided in respect of the energy-using product under subsection 6(1) of the Accounting for Imported Goods and Payment of Duties Regulations and must be provided before the product is released under the Customs Act.

Exemptions from Certain Provisions of the Act

Exemption — product to be modified

8 (1) A dealer is exempt from the application of paragraph 4(1)(a) of the Act if the dealer, for the purpose of modifying an energy-using product to comply with the applicable energy efficiency standard, ships the product from the province in which it was manufactured to another province or imports the product into Canada.

Requirements

(2) The dealer must

- (a) ensure that the product is brought into compliance with the applicable energy efficiency standard within 90 days after the day on which the product is shipped or imported;

- (b) despite subsection 5(2), provide the information referred to in subsection 5(1) within 120 days after the day on which the product is shipped or imported; and

- (c) if requested by the Minister, provide the Minister with any other information that is necessary to establish that the product has been brought into compliance with the applicable energy efficiency standard.

Exemption — incorporation into product for export

9 A dealer is exempt from the application of sections 4 and 5 of the Act with respect to the shipment or importation of an energy-using product that is to be incorporated into any other product that is to be exported from Canada.

Exemption — product to be exported

10 A dealer is exempt from the application of sections 4 and 5 of the Act if the dealer, for the purpose of exporting the energy-using product from Canada, ships the product from the province in which it was manufactured to another province or imports the product into Canada.

Exemption — motors with same unique motor identifier

11 A dealer is exempt from the application of section 5 of the Act in respect of a motor if

- (a) the information has been provided in respect of a motor that has the same unique motor identifier; and

- (b) the motor is at least as energy efficient as the motor for which the information was provided.

PART 2

Energy-Using Products

DIVISION 1

Household Appliances

Interpretation

Definitions

12 The following definitions apply in this Division.

10 C.F.R. Appendix D2 means Appendix D2 to Subpart B, Part 430 of Title 10 to the United States Code of Federal Regulations, entitled Uniform Test Method for Measuring the Energy Consumption of Clothes Dryers, as amended from time to time. (appendice D2 10 C.F.R.)

CSA C300-00 means the CSA standard CAN/CSA-C300-00 entitled Energy Performance and Capacity of Household Refrigerators, Refrigerator-Freezers, and Freezers. (CSA C300-00)

CSA C300-12 means the CSA standard CAN/CSA-C300-12 entitled Energy Performance and Capacity of Household Refrigerators, Refrigerator-Freezers, Freezers and Wine Chillers. (CSA C300-12)

CSA C300-15 means the CSA standard CAN/CSA-C300-15 entitled Energy Performance and Capacity of Household Refrigerators, Refrigerator-Freezers, Freezers and Wine Chillers. (CSA C300-15)

CSA C358-03 means the CSA standard CAN/CSA-C358-03 entitled Energy Consumption Test Methods for Household Electric Ranges. (CSA C358-03)

CSA C360-03 means the CSA standard CAN/CSA-C360-03 entitled Energy Performance, Water Consumption and Capacity of Household Clothes Washers. (CSA C360-03)

CSA C360-13 means the CSA standard CAN/CSA-C360-13 entitled Energy Performance, Water Consumption and Capacity of Household Clothes Washers. (CSA C360-13)

CSA C361-12 means the CSA standard CAN/CSA-C361-12 entitled Test Method for Measuring Energy Consumption and Drum Volume of Electrically Heated Household Tumble-Type Clothes Dryers. (CSA C361-12)

CSA C361-92 means the CSA standard CAN/CSA-C361-92 entitled Test Method for Measuring Energy Consumption and Drum Volume of Electrically Heated Household Tumble-Type Clothes Dryers. (CSA C361-92)

Labelling

EnerGuide label

13 (1) An energy-using product prescribed in any of Subdivisions A to G of this Division must be labelled in the form set out in Schedule 1.

Manner of labelling

(2) The label must be an adhesive tag, flap tag or hang tag that is attached to the product so that the tag is readily visible when the product is viewed from the front.

Paper — adhesive and flap tags

14 (1) The paper that is used for adhesive tags or flap tags must weigh, exclusive of the release liner and adhesive, not less than the equivalent of 26.31 kg (58 pounds) per 500 sheets measuring 63.5 cm (25 inches) by 96.52 cm (38 inches).

Adhesive — adhesive and flap tags

(2) The adhesive that is used to attach an adhesive tag or a flap tag to an energy-using product must

- (a) render the tag easily removable from the product without the use of a tool or any liquid other than water; and

- (b) have an adhesion capacity that is sufficient to prevent the tag from being dislodged from the product under normal handling conditions.

Paper — hang tags

15 (1) The paper that is used for hang tags must weigh not less than the equivalent of 49.9 kg (110 pounds) per 500 sheets measuring 64.77 cm (25.5 inches) by 77.47 cm (30.5 inches).

Attachment material — hang tags

(2) The material that is used to attach a hang tag to an energy-using product must be of sufficient strength to ensure that when gradual pressure is applied to the tag by pulling it away from the product, the tag will tear before the material breaks.

SUBDIVISION A

Clothes Dryers

Definition of clothes dryer

16 In this Subdivision, clothes dryer means a household tumble-type clothes dryer that is electrically operated.

Size category

17 For the purposes of these Regulations, the size category of a clothes dryer is

- (a) compact, if it has a drum capacity of less than 125 L (4.4 cubic feet); or

- (b) standard, if it has a drum capacity of 125 L (4.4 cubic feet) or more.

Energy-using product

18 (1) A clothes dryer is prescribed as an energy-using product.

Limit

(2) However, for the purposes of sections 4, 5, 13 to 15 and 19, a clothes dryer is not considered to be an energy-using product unless it is manufactured on or after February 3, 1995.

Energy efficiency standards

19 (1) The energy efficiency standards set out in column 2 of the table to this section apply to clothes dryers that are manufactured during the periods set out in column 3.

Testing standard

(2) A clothes dryer complies with the energy efficiency standard if it meets that standard when tested in accordance with testing procedures established by the standard set out in column 1 that are applicable to a clothes dryer as defined in section 16.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

|---|---|---|---|

1 |

CSA C361-92 |

CSA C361-92, Table 8.1 |

On or after February 3, 1995 and before January 1, 2015 |

2 |

CSA C361-12 or 10 C.F.R. Appendix D2 |

CSA C361-12, Table 1 |

On or after January 1, 2015 |

Information- 20 For the purpose of subsection 5(1) of the Act, the information set out in column 3 of the table to this section must be collected in accordance with the standard set out in column 2 and provided to the Minister in respect of a clothes dryer described in column 1.

TABLE

| Item |

Column 1 Energy-using Product |

Column 2 Standard |

Column 3 Information |

|---|---|---|---|

1 |

Clothes dryers manufactured on or after February 3, 1995 and before January 1, 2015 |

CSA C361-92 |

|

2 |

Clothes dryers manufactured on or after January 1, 2015 |

CSA C361-12 or 10 C.F.R. Appendix D2 |

|

SUBDIVISION B

Clothes Washers

Definition of clothes washer

21 In this Subdivision, clothes washer means an electrically operated clothes washer that does not require mechanical fastening to a floor or wall, is top- or front-loaded and has an internal control system that regulates the water temperature without the need for user intervention after the machine is set in operation.

Size category

22 For the purposes of these Regulations, the size category of a clothes washer is

- (a) compact, if it has a container capacity of less than 45 L (1.6 cubic feet); or

- (b) standard, if it has a container capacity of 45 L (1.6 cubic feet) or more.

Energy-using product

23 (1) A clothes washer is prescribed as an energy-using product.

Limits

(2) However, a clothes washer is not considered to be an energy-using product

- (a) for the purposes of sections 4, 5 and 24, unless it is manufactured on or after February 3, 1995; and

- (b) for the purposes of sections 13 to 15, unless it is a household clothes washer and it is manufactured on or after February 3, 1995.

Energy efficiency standards

24 (1) The energy efficiency standards set out in column 3 of the table to this section apply to clothes washers described in column 1 that are manufactured during the periods set out in column 4.

Testing standard

(2) A clothes washer complies with the energy efficiency standard if it meets that standard when tested in accordance with testing procedures established by the standard set out in column 2 that are applicable to a clothes washer as defined in section 21.

TABLE

| Item |

Column 1 Energy-using Product |

Column 2 Standard |

Column 3 Energy Efficiency Standard |

Column 4 Period of Manufacture |

|---|---|---|---|---|

1 |

Clothes washers |

CSA C360-03 |

CSA C360-03, Table 9 |

On or after February 3, 1995 and before January 1, 2007 |

2 |

Clothes washers, other than household clothes washers |

CSA C360-03 |

CSA C360-03, Table 10 |

On or after January 1, 2007 and before January 8, 2013 |

3 |

Clothes washers, other than household clothes washers |

CSA C360-03 |

CSA C360-13, Table 11 |

On or after January 8, 2013 and before January 1, 2018 |

4 |

Clothes washers that are top-loaded, other than household clothes washers |

CSA C360-13 |

Modified energy factor ≥ 38.23 L/kWh/cycle |

On or after January 1, 2018 |

5 |

Clothes washers that are front-loaded, other than household clothes washers |

CSA C360-13 |

Modified energy factor ≥ 56.63 L/kWh/cycle |

On or after January 1, 2018 |

6 |

Household clothes washers |

CSA C360-03 |

CSA C360-03, Table 10 |

On or after January 1, 2007 and before March 7, 2015 |

7 |

Household clothes washers |

CSA C360-13 |

CSA C360-13, Table 9 |

On or after March 7, 2015 and before January 1, 2018 |

8 |

Household clothes washers |

CSA C360-13 |

CSA C360-13, Table 10 |

On or after January 1, 2018 |

Information- 25 For the purpose of subsection 5(1) of the Act, the information set out in column 3 of the table to this section must be collected in accordance with the standard set out in column 2 and provided to the Minister in respect of a clothes washer described in column 1.

TABLE

| Item |

Column 1 Energy-using Product |

Column 2 Standard |

Column 3 Information |

|---|---|---|---|

1 |

Clothes washers manufactured on or after February 3, 1995 and before March 7, 2015 |

CSA C360-03 |

|

2 |

Household clothes washers manufactured on or after March 7, 2015 |

CSA C360-13 |

|

3 |

Clothes washers, other than household clothes washers, manufactured on or after March 7, 2015 and before January 1, 2018 |

CSA C360-03 |

|

4 |

Clothes washers, other than household clothes washers, manufactured on or after January 1, 2018 |

CSA C360-13 |

|

SUBDIVISION C

Integrated Clothes Washer-Dryers

Definitions

26 The following definitions apply in this Subdivision.

combination clothes washer-dryer means a household appliance that has

- (a) a clothes washer function and clothes dryer function that utilize the same drum;

- (b) a common control panel for both functions; and

- (c) one power source. (laveuse-sécheuse combinée)

integrated clothes washer-dryer means

- (a) a household appliance that consists of a clothes washer component and a clothes dryer component located above, below or beside it, that is powered by one power source and that has its control panel located on one of the components; or

- (b) a combination clothes washer-dryer. (laveuse-sécheuse)

V means

- (a) in the case of an integrated clothes washer-dryer that is not a combination clothes washer-dryer, the volumes, expressed in litres, of the basket for the clothes washer component and of the drum for the clothes dryer component; or

- (b) in the case of an integrated clothes washer-dryer that is a combination clothes washer-dryer, the volume, expressed in litres, of the drum. (V)

Size category — other than combination clothes washer-dryer

27 (1) For the purposes of these Regulations, the size category of an integrated clothes washer-dryer that is not a combination clothes washer-dryer is

- (a) compact, if it has a clothes dryer component with a drum capacity of less than 125 L (4.4 cubic feet) and a clothes washer component with a basket capacity of less than 45 L (1.6 cubic feet); or

- (b) standard, if it has a clothes dryer component with a drum capacity of 125 L (4.4 cubic feet) or more and a clothes washer component with a basket capacity of 45 L (1.6 cubic feet) or more.

Size category — combination clothes washer-dryer

(2) For the purposes of these Regulations, the size category of an integrated clothes washer-dryer that is a combination clothes washer is

- (a) compact, if it has a drum capacity of less than 45 L (1.6 cubic feet); or

- (b) standard, if it has a drum capacity of 45 L (1.6 cubic feet) or more.

Type

28 For the purposes of these Regulations, an integrated clothes washer-dryer is one of the following types, namely, combination, over/under or side-by-side.

Energy-using product

29 (1) An integrated clothes washer-dryer is prescribed as an energy-using product.

Limit

(2) However, for the purposes of sections 4, 5, 13 to 15 and 30, an integrated clothes washer-dryer is not considered to be an energy-using product unless it is manufactured on or after February 3, 1995.

Energy efficiency standards

30 (1) The energy efficiency standards set out in column 2 of the table to this section apply to integrated clothes washer-dryers that are manufactured during the periods set out in column 3.

Testing standard

(2) An integrated clothes washer-dryer complies with the energy efficiency standard if it meets that standard when tested in accordance with testing procedures established by the standard set out in column 1 that are applicable to an integrated clothes washer-dryer as defined in section 26.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

|---|---|---|---|

1 |

CSA C360-03 for clothes washer function CSA C361-92 for clothes dryer function |

CSA C360-03, Table 9, for clothes washer function CSA C361-92, Table 8.1, for clothes dryer function |

On or after February 3, 1995 and before January 1, 2007 |

2 |

CSA C360-03 for clothes washer function CSA C361-92 for clothes dryer function |

CSA C360-03, Table 10, for clothes washer function CSA C361-92, Table 8.1, for clothes dryer function |

On or after January 1, 2007 and before March 7, 2015 |

3 |

CSA C360-13 for clothes washer function CSA C361-12 or 10 C.F.R. Appendix D2 for clothes dryer function |

CSA C360-13, Table 9, for clothes washer function CSA C361-12, Table 1, for clothes dryer function |

On or after March 7, 2015 and before January 1, 2018 |

4 |

CSA C360-13 for clothes washer function CSA C361-12 or 10 C.F.R. Appendix D2 for clothes dryer function |

CSA C360-13, Table 10, for clothes washer function CSA C361-12, Table 1, for clothes dryer function |

On or after January 1, 2018 |

Information

31 For the purpose of subsection 5(1) of the Act, the information set out in column 3 of the table to this section must be collected in accordance with the standard set out in column 2 and provided to the Minister in respect of an integrated clothes washer-dryer described in column 1.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

|---|---|---|---|

1 |

Integrated clothes washer-dryers manufactured on or after February 3, 1995 and before March 7, 2015 |

CSA C360-03 for clothes washer function CSA C361-92 for clothes dryer function |

|

2 |

Integrated clothes washer-dryers manufactured on or after March 7, 2015 |

CSA C360-13 for clothes washer function CSA C361-12 or 10 C.F.R. Appendix D2 for clothes dryer function |

|

SUBDIVISION D

Dishwashers

Definitions

32 The following definitions apply in this Subdivision.

CSA C373-04 means the CSA standard CAN/CSA-C373-04 entitled Energy Consumption Test Methods and Limits for Household Dishwashers. (CSA C373-04)

CSA C373-14 means the CSA standard CAN/CSA-C373-14 entitled Energy Performance and Water Consumption of Household Dishwashers. (CSA C373-14)

dishwasher means an electrically operated automatic household dishwasher. (lave-vaisselle)

Size category

33 For the purposes of these Regulations, the size category of a dishwasher is

- (a) compact, if it has a capacity of less than eight place settings and six serving pieces; or

- (b) standard, if it has a capacity that is equal to or greater than eight place settings and six serving pieces.

Type

34 For the purposes of these Regulations, a dishwasher is one of the following types:

- (a) built-in, if it is designed to be permanently connected to a water and electric supply in a dwelling; or

- (b) portable, if it is designed not to be permanently connected to a water and electric supply in a dwelling.

Labelling — total annual energy consumption

35 In respect of a dishwasher that is manufactured on or after January 1, 2010, a reference to “annual energy consumption” in Schedule 1 is to be read as a reference to “total annual energy consumption”.

Energy-using product

36 (1) A dishwasher is prescribed as an energy-using product.

Limit

(2) However, for the purposes of sections 4, 5, 13 to 15 and 37, a dishwasher is not considered to be an energy-using product unless it is manufactured on or after February 3, 1995.

Energy efficiency standards

37 (1) The energy efficiency standards set out in column 3 of the table to this section apply to dishwashers described in column 1 that are manufactured during the periods set out in column 4.

Testing standard

(2) A dishwasher complies with the energy efficiency standard if it meets that standard when tested in accordance with testing procedures established by the standard set out in column 2 that are applicable to a dishwasher as defined in section 32.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

Column 4 |

|---|---|---|---|---|

1 |

Dishwashers |

CSA C373-04 |

CSA C373-04, Table 2 |

On or after February 3, 1995 and before January 1, 2010 |

2 |

Dishwashers that are standard |

CSA C373-04 |

Total annual energy consumption ≤ 355 kWh |

On or after January 1, 2010 and before May 30, 2013 |

3 |

Dishwashers that are standard |

CSA C373-14 |

Total annual energy consumption ≤ 307 kWh |

On or after May 30, 2013 |

4 |

Dishwashers that are compact |

CSA C373-04 |

Total annual energy consumption ≤ 260 kWh |

On or after January 1, 2010 and before May 30, 2013 |

5 |

Dishwashers that are compact |

CSA C373-14 |

Total annual energy consumption ≤ 222 kWh |

On or after May 30, 2013 |

- Information

- 38 For the purpose of subsection 5(1) of the Act, the information set out in column 3 of the table to this section must be collected and provided to the Minister in respect of a dishwasher described in column 1 and, if applicable, the information must be collected in accordance with the standard set out in column 2.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

|---|---|---|---|

1 |

Dishwashers manufactured on or after February 3, 1995 and before January 1, 2010 |

CSA C373-04, for information set out in paragraphs (b) to (d) |

|

2 |

Dishwashers manufactured on or after January 1, 2010 and before May 30, 2013 |

CSA C373-04, for information set out in paragraphs (b) to (e) |

|

3 |

Dishwashers manufactured on or after May 30, 2013 |

CSA C373-14, for information set out in paragraphs (b) to (d) |

|

SUBDIVISION E

Refrigerators and Combination Refrigerator-Freezers

Definitions

39 The following definitions apply in this Subdivision.

combination refrigerator-freezer means a household combination refrigerator-freezer that has

- (a) a defrost system, including a compressor-cycled automatic defrost system; and

- (b) a capacity of 1 100 L (39 cubic feet) or less. (réfrigérateur-congélateur)

compressor-cycled automatic defrost system means a defrost system in which the defrosting action for the refrigerated spaces occurs using the natural warming of the evaporator and that is automatically initiated when the compressor is cycled on and automatically terminated when the compressor is cycled off. (dispositif de dégivrage automatique à cycle du compresseur)

refrigerator means a household refrigerator that has a capacity of 1 100 L (39 cubic feet) or less and that has a defrost system, including a compressor-cycled automatic defrost system. It includes a wine chiller but does not include a household refrigerator that uses an absorption refrigeration system. (réfrigérateur)

Type 5A combination refrigerator-freezer means a combination refrigerator-freezer that is manufactured on or after December 31, 2005, is capable of dispensing ice through the cabinet door and is equipped with a bottom-mounted freezer and an automatic defrost system. (réfrigérateur-congélateur de type 5A)

- Size category

- 40 For the purposes of these Regulations, the size category of a refrigerator or combination refrigerator-freezer is the capacity range set out below within which the actual size of the product falls or that is closest to the actual size of the product:

- (a) less than 70.80 L (2.5 cubic feet);

- (b) 70.80 to 124.61 L (2.5 to 4.4 cubic feet);

- (c) 127.44 to 181.25 L (4.5 to 6.4 cubic feet);

- (d) 184.08 to 237.89 L (6.5 to 8.4 cubic feet);

- (e) 240.73 to 294.53 L (8.5 to 10.4 cubic feet);

- (f) 297.37 to 351.18 L (10.5 to 12.4 cubic feet);

- (g) 354.01 to 407.82 L (12.5 to 14.4 cubic feet);

- (h) 410.65 to 464.46 L (14.5 to 16.4 cubic feet);

- (i) 467.29 to 521.10 L (16.5 to 18.4 cubic feet);

- (j) 523.93 to 577.74 L (18.5 to 20.4 cubic feet);

- (k) 580.57 to 634.38 L (20.5 to 22.4 cubic feet);

- (l) 637.21 to 691.02 L (22.5 to 24.4 cubic feet);

- (m) 693.85 to 747.66 L (24.5 to 26.4 cubic feet);

- (n) 750.50 to 804.30 L (26.5 to 28.4 cubic feet);

- (o) 807.14 to 860.95 L (28.5 to 30.4 cubic feet); or

- (p) 863.66 to 1 100 L (30.5 to 39.0 cubic feet).

Type

41 For the purposes of these Regulations, a refrigerator or combination refrigerator-freezer is one of the following types:

- (a) if it was manufactured on or after February 3, 1995 and before January 1, 2008, a type described in any of the product types (1) to (7) and (11) to (15) of Table 1 to CSA C300-00 or a Type 5A combination refrigerator-freezer; or

- (b) if it is manufactured on or after January 1, 2008, a type described in any of the product types (1) to (7), (11) to (15), (19) and (20) of Table 1 to CSA C300-12.

Energy-using products

42 (1) Refrigerators and combination refrigerator-freezers are prescribed as energy-using products.

Limit

(2) However, for the purposes of sections 4, 5, 13 to 15 and 43, a refrigerator or combination refrigerator-freezer is not considered to be an energy-using product unless it is manufactured on or after February 3, 1995.

Energy efficiency standards

43 (1) The energy efficiency standards set out in column 3 of the table to this section apply to refrigerators and combination refrigerator-freezers described in column 1 that are manufactured during the periods set out in column 4.

Testing standard — refrigerators

(2) A refrigerator complies with the energy efficiency standard if it meets that standard when tested in accordance with testing procedures established by the standard set out in column 2 that are applicable to a refrigerator as defined in section 39.

Testing standard — combination-refrigerator freezers

(3) A combination refrigerator-freezer complies with the energy efficiency standard if it meets that standard when tested in accordance with testing procedures established by the standard set out in column 2 that are applicable to a combination-refrigerator freezer as defined in section 39.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

Column 4 |

|---|---|---|---|---|

1 |

Refrigerators and combination refrigerator-freezers, other than Type 5A combination refrigerator-freezers |

CSA C300-00 |

CSA C300-00, Table 1, column B |

On or after February 3, 1995 and before January 1, 2008 |

2 |

Type 5A combination refrigerator-freezers |

CSA C300-00 |

Annual energy consumption ≤ (0.18 × adjusted volume) + 539 |

On or after December 31, 2005 and before January 1, 2008 |

3 |

Refrigerators and combination refrigerator-freezers |

CSA C300-12 |

CSA C300-12, Table 1 |

On or after January 1, 2008 and before September 15, 2014 |

4 |

Refrigerators and combination refrigerator-freezers |

CSA C300-15 |

CSA C300-15, Table 1 |

On or after September 15, 2014 |

- Information

- 44 (1) For the purpose of subsection 5(1) of the Act, the following information must be provided to the Minister in respect of a refrigerator or combination refrigerator-freezer:

- (a) its type;

- (b) the volume of its fresh food compartment;

- (c) the volume of its freezer compartment, if any;

- (d) its adjusted volume; and

- (e) its annual energy consumption, expressed in kilowatt hours.

Standard

(2) The information must be collected in accordance with one of the following standards:

- (a) CSA C300-00, if the product was manufactured on or after February 3, 1995 and before January 1, 2008;

- (b) CSA C300-12, if the product was manufactured on or after January 1, 2008 and before September 15, 2014; or

- (c) CSA C300-15, if the product is manufactured on or after September 15, 2014.

SUBDIVISION F

Freezers

Definitions

45 The following definitions apply in this Subdivision.

freezer means a household freezer that has a capacity of 850 L (30 cubic feet) or less. (congélateur)

Type 10A chest freezer means a chest freezer that is manufactured on or after December 31, 2003, is accessible from the top and is equipped with an automatic defrost system. (congélateur coffre de type 10A)

Size category

46 For the purposes of these Regulations, the size category of a freezer is the capacity range set out below within which the actual size of the product falls or that is closest to the actual size of the product:

- (a) less than 155.76 L (5.5 cubic feet);

- (b) 155.76 to 209.57 L (5.5 to 7.4 cubic feet);

- (c) 212.40 to 266.21 L (7.5 to 9.4 cubic feet);

- (d) 269.04 to 322.85 L (9.5 to 11.4 cubic feet);

- (e) 325.68 to 379.49 L (11.5 to 13.4 cubic feet);

- (f) 383.32 to 436.13 L (13.5 to 15.4 cubic feet);

- (g) 438.96 to 492.77 L (15.5 to 17.4 cubic feet);

- (h) 495.60 to 549.41 L (17.5 to 19.4 cubic feet);

- (i) 552.24 to 606.05 L (19.5 to 21.4 cubic feet);

- (j) 608.88 to 662.69 L (21.5 to 23.4 cubic feet);

- (k) 665.52 to 719.33 L (23.5 to 25.4 cubic feet);

- (l) 722.16 to 775.97 L (25.5 to 27.4 cubic feet);

- (m) 778.80 to 832.61 L (27.5 to 29.4 cubic feet); or

- (n) 835.44 to 850 L (29.5 to 30.0 cubic feet).

Type

47 For the purposes of these Regulations, a freezer is one of the following types:

- (a) if it was manufactured on or after February 3, 1995 and before January 1, 2008, a type described in any of the product types (8) to (10) and (16) to (18) of Table 1 to CSA C300-00 or a Type 10A chest freezer; or

- (b) if it is manufactured on or after January 1, 2008, a type described in any of the product types (8) to (10A) and (16) to (18) of Table 1 to CSA C300-12.

Energy-using product

48 (1) A freezer is prescribed as an energy-using product.

Limit

(2) However, for the purposes of sections 4, 5, 13 to 15 and 49, a freezer is not considered to be an energy-using product unless it is manufactured on or after February 3, 1995.

Energy efficiency standards

49 (1) The energy efficiency standards set out in column 3 of the table to this section apply to freezers described in column 1 that are manufactured during the periods set out in column 4.

Testing standard

(2) A freezer complies with the energy efficiency standard if it meets that standard when tested in accordance with testing procedures established by the standard set out in column 2 that are applicable to a freezer as defined in section 45.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

Column 4 |

|---|---|---|---|---|

1 |

Freezers other than Type 10A chest freezers |

CSA C300-00 |

CSA C300-00, Table 1, column B |

On or after February 3, 1995 and before January 1, 2008 |

2 |

Type 10A chest freezers |

CSA C300-00 |

Annual energy consumption ≤ (0.52 × adjusted volume) + 211.5 |

On or after December 31, 2003 and before January 1, 2008 |

3 |

Freezers |

CSA C300-12 |

CSA C300-12, Table 1 |

On or after January 1, 2008 and before September 15, 2014 |

4 |

Freezers |

CSA C300-15 |

CSA C300-15, Table 1 |

On or after September 15, 2014 |

- Information

- 50 (1) For the purpose of subsection 5(1) of the Act, the following information must be provided to the Minister in respect of a freezer:

- (a) its type;

- (b) its total refrigerated volume;

- (c) its adjusted volume;

- (d) its annual energy consumption, expressed in kilowatt hours; and

- (e) its ice freezing capacity, expressed in kilograms per 24 hours.

Standard

(2) The information must be collected in accordance with one of the following standards:

- (a) CSA C300-00, if the product was manufactured on or after February 3, 1995 and before January 1, 2008;

- (b) CSA C300-12, if the product was manufactured on or after January 1, 2008 and before September 15, 2014; or

- (c) CSA C300-15, if the product is manufactured on or after September 15, 2014.

SUBDIVISION G

Electric Ranges

Definitions

51 The following definitions apply in this Subdivision.

conventional cooking top means a cooking top that is not a modular cooking top. (table de cuisson traditionnelle)

E means energy consumption, expressed in kilowatt hours per month. (E)

electric range means a household electric range. It does not include a portable range that is designed for an electrical supply of 120 V or a microwave oven. (cuisinière électrique)

modular cooking top means a cartridge that consists of at least one surface element and that can be plugged into a receptacle on the surface of an electric range. (table de cuisson modulaire)

Size category

52 For the purposes of these Regulations, the size category of an electric range that has at least one surface element and at least one oven is one of the following, based on the product’s exterior width:

- (a) 60.96 cm (24 inches);

- (b) 76.2 cm (30 inches);

- (c) 91.44 cm (36 inches); or

- (d) 121.92 cm (48 inches).

Type

53 For the purposes of these Regulations, an electric range is one of the following types:

- (a) if it has at least one oven, either self-cleaning or non-self-cleaning; and

- (b) if it has no oven, all models.

Energy-using product

54 (1) An electric range is prescribed as an energy-using product.

Limit

(2) However, for the purposes of sections 4, 5, 13 to 15 and 55, an electric range is not considered to be an energy-using product unless it is manufactured on or after February 3, 1995.

Energy efficiency standards

55 (1) The energy efficiency standards set out in column 2 of the table to this section apply to electric ranges described in column 1 that are manufactured during the periods set out in column 3.

Testing standard

(2) An electric range complies with the energy efficiency standard if it meets that standard when tested in accordance with testing procedures established by CSA C358-03 that are applicable to an electric range as defined in section 51.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

|---|---|---|---|

1 |

Electric ranges that have at least one surface element and at least one oven |

E ≤ 0.93 V + 14.3 |

On or after February 3, 1995 and before August 1, 2003 |

2 |

Electric ranges that have at least one surface element and at least one oven |

CSA C358-03, clause 8(a) |

On or after August 1, 2003 |

3 |

Electric ranges that have at least one oven but no surface elements |

E ≤ 38 |

On or after February 3, 1995 and before August 1, 2003 |

4 |

Electric ranges that have at least one oven but no surface elements |

CSA C358-03, clause 8(c) |

On or after August 1, 2003 |

5 |

Electric ranges that are counter-mounted and have at least one surface element on a conventional cooking top but have no oven |

E ≤ 34 |

On or after February 3, 1995 and before August 1, 2003 |

6 |

Electric ranges that are counter-mounted and have at least one surface element on a modular cooking top but have no oven |

E ≤ 43 |

On or after February 3, 1995 and before August 1, 2003 |

7 |

Electric ranges that are counter-mounted and have at least one surface element but have no oven |

CSA C358-03, clause 8(b) |

On or after August 1, 2003 |

- Information

- 56 For the purpose of subsection 5(1) of the Act, the information set out in column 2 of the table to this section must be collected in accordance with CSA C358-03 and provided to the Minister in respect of an electric range described in column 1.

TABLE

| Item |

Column 1 |

Column 2 |

|---|---|---|

1 |

Electric ranges that have at least one surface element and at least one oven and that were manufactured on or after February 3, 1995 and before August 1, 2003 |

|

2 |

Electric ranges that have at least one surface element and at least one oven and that are manufactured on or after August 1, 2003 |

|

3 |

Electric ranges that have at least one oven but no surface element and that were manufactured on or after February 3, 1995 and before August 1, 2003 |

|

4 |

Electric ranges that have at least one oven but no surface element and that are manufactured on or after August 1, 2003 |

|

5 |

Electric ranges that are counter-mounted, have at least one surface element but no oven and were manufactured on or after February 3, 1995 and before August 1, 2003 |

|

6 |

Electric ranges that are counter-mounted, have at least one surface element but no oven and are manufactured on or after August 1, 2003 |

|

SUBDIVISION H

Gas Ranges

Definition of gas range

57 In this Subdivision, gas range means a household propane or natural gas range that has an electrical power source, is used for food preparation and provides at least one of the following functions:

- (a) surface cooking;

- (b) oven cooking; and

- (c) broiling.

Energy-using product

58 (1) A gas range is prescribed as an energy-using product.

Limit

(2) However, for the purposes of sections 4, 5 and 59, a gas range is not considered to be an energy-using product unless it is manufactured on or after February 3, 1995.

Energy efficiency standard

59 The energy efficiency standard that applies to a gas range is that it must not have a continuously burning pilot light.

Information

60 For the purpose of subsection 5(1) of the Act, the following information must be collected in accordance with CSA C358-03 and provided to the Minister in respect of a gas range:

- (a) the volume of usable oven space, expressed in litres;

- (b) information that indicates whether the product is built-in or free-standing; and

- (c) the broiler configuration, namely, open or closed.

SUBDIVISION I

Dehumidifiers

Definitions

61 The following definitions apply in this Subdivision.

CSA C749-07 means the CSA standard CAN/CSA-C749-07 entitled Performance of Dehumidifiers. (CSA C749-07)

CSA C749-94 means the CSA standard CAN/CSA-C749-94 entitled Performance of Dehumidifiers. (CSA C749-94)

dehumidifier means a factory-assembled electric device that removes moisture from the air, is mechanically refrigerated and has a water removal capacity of not more than 87.5 L/day (185 U.S. pints/day). (déshumidificateur)

Energy-using product

62 (1) A dehumidifier is prescribed as an energy-using product.

Limit

(2) However, for the purposes of sections 4, 5 and 63, a dehumidifier is not considered to be an energy-using product unless it is manufactured on or after December 31, 1998.

Energy efficiency standards

63 (1) The energy efficiency standards set out in column 3 of the table to this section apply to dehumidifiers described in column 1 that are manufactured during the periods set out in column 4.

Testing standard

(2) A dehumidifier complies with the energy efficiency standard if it meets that standard when tested in accordance with testing procedures established by the standard set out in column 2 that are applicable to a dehumidifier as defined in section 61.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

Column 4 |

|---|---|---|---|---|

1 |

Dehumidifiers |

CSA C749-94 |

CSA C749-94, clause 4.2 |

On or after December 31, 1998 and before October 1, 2007 |

2 |

Dehumidifiers |

CSA C749-07 |

CSA C749-07, Table 1 |

On or after October 1, 2007 and before October 1, 2012 |

3 |

Dehumidifiers that have a water removal capacity of ≤ 16.6 L/day |

CSA C749-07 |

Energy factor ≥ 1.35 L/kWh |

On or after October 1, 2012 |

4 |

Dehumidifiers that have a water removal capacity of > 16.6 L/day but ≤ 21.3 L/day |

CSA C749-07 |

Energy factor ≥ 1.5 L/kWh |

On or after October 1, 2012 |

5 |

Dehumidifiers that have a water removal capacity of > 21.3 L/day but ≤ 25.5 L/day |

CSA C749-07 |

Energy factor ≥ 1.6 L/kWh |

On or after October 1, 2012 |

6 |

Dehumidifiers that have a water removal capacity of > 25.5 L/day but ≤ 35.5 L/day |

CSA C749-07 |

Energy factor ≥ 1.7 L/kWh |

On or after October 1, 2012 |

7 |

Dehumidifiers that have a water removal capacity of > 35.5 L/day |

CSA C749-07 |

Energy factor ≥ 2.5 L/kWh |

On or after October 1, 2012 |

- Information

- 64 For the purpose of subsection 5(1) of the Act, the information set out in column 3 of the table to this section must be collected in accordance with the standard set out in column 2 and provided to the Minister in respect of a dehumidifier described in column 1.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

|---|---|---|---|

1 |

Dehumidifiers manufactured before October 1, 2007 |

CSA C749-94 |

|

2 |

Dehumidifiers manufactured on or after October 1, 2007 |

CSA C749-07 |

|

[65 to 106 reserved]

DIVISION 2

Air Conditioners, Condensing Units and Chillers

Interpretation

Definitions

107 The following definitions apply in this Division.

CSA C656-05 means the CSA standard CAN/CSA-C656-05 entitled Performance Standard for Split-System and Single-Package Central Air Conditioners and Heat Pumps. (CSA C656-05)

CSA C656-14 means the CSA standard CSA-C656-14 entitled Performance Standard for Split-System and Single-Package Central Air Conditioners and Heat Pumps. (CSA C656-14)

CSA C746-06 means the CSA standard CAN/CSA-C746-06 entitled Performance Standard for Rating Large and Single Packaged Vertical Air Conditioners and Heat Pumps. (CSA C746-06)

CSA C746-98 means the CSA standard CAN/CSA-C746-98 entitled Performance Standard for Rating Large Air Conditioners and Heat Pumps. (CSA C746-98)

small-duct and high-velocity, with respect to a single package central air conditioner or a split-system central air conditioner, means one that has an indoor blower and coil combination that

- (a) produces at least 300 Pa (1.2 inches of water) external static pressure when operated at an air volume rate of 104 to 165 L/s (220 to 350 cubic feet/minute) per nominal ton of cooling; and

- (b) uses room outlets that produce velocities greater than 5 m/s (1,000 feet/minute) and that each have an area less than 39 cm2 (6 square inches). (à grand débit et à petits conduits)

SUBDIVISION A

Room Air Conditioners

Definitions

108 The following definitions apply in this Subdivision.

CEER means the combined energy efficiency ratio of the product, expressed in British thermal units per watt hour, that constitutes a single measure of its energy efficiency and that integrates standby mode and off mode energy use with on mode energy use. (CEER)

CSA C368.1 means the CSA standard CAN/CSA-C368.1-M90 entitled Performance Standard for Room Air Conditioners. (CSA C368.1)

CSA C370 means the CSA standard CAN/CSA-C370-09 entitled Cooling Performance of Portable Air Conditioners. (CSA C370)

CSA C62301 means the CSA standard CAN/CSA-C62301:11 entitled Household Electrical Appliances – Measurement of Standby Power. (CSA C62301)

off mode means the mode in which a room air conditioner, while connected to mains power, provides no air circulation and cannot be switched into another mode with a remote control unit, internal signal or internal timer. (mode arrêt)

on mode means the mode in which a room air conditioner, while connected to mains power, cools or heats the conditioned space or circulates air with its fan or blower. (mode marche)

portable air conditioner means a single package air conditioner, with or without mounted wheels, that is portable and that

- (a) is represented by the configurations shown in Table 1 of CSA C370; and

- (b) has a cooling capacity of less than 19 kW (65,000 Btu/h). (climatiseur portatif)

room air conditioner means a single-phase electric air conditioner that has a cooling capacity of 10.55 kW (36,000 Btu/h) or less. It does not include a packaged terminal air conditioner, a portable air conditioner or a single package vertical air conditioner. (climatiseur individuel)

standby mode means the mode in which a room air conditioner, while connected to mains power, provides no air circulation, but can be switched into another mode with a remote control unit, internal signal or internal timer. (mode veille)

Type

109 For the purposes of these Regulations, a room air conditioner is one of the following types:

- (a) 120 V louvred with reverse cycle;

- (b) 120 V louvred without reverse cycle;

- (c) 120 V non-louvred with reverse cycle;

- (d) 120 V non-louvred without reverse cycle;

- (e) 120 V casement-only;

- (f) 120 V casement-slider;

- (g) 240 V louvred with reverse cycle;

- (h) 240 V louvred without reverse cycle;

- (i) 240 V non-louvred with reverse cycle;

- (j) 240 V non-louvred without reverse cycle;

- (k) 240 V casement-only; or

- (l) 240 V casement-slider.

Cooling capacity category

110 For the purposes of these Regulations, the cooling capacity category of a room air conditioner is

- (a) if the product was manufactured before June 1, 2014, the applicable cooling capacity range set out in Table 2 of CSA C368.1; or

- (b) if the product is manufactured on or after June 1, 2014, the applicable cooling capacity category set out in column 2 of the table to section 112.

Energy-using product

111 (1) A room air conditioner is prescribed as an energy-using product.

Limit

(2) However, for the purposes of sections 4, 5, 13 to 15 and 112, a room air conditioner is not considered to be an energy-using product unless it is manufactured on or after February 3, 1995.

Energy efficiency standards

112 (1) The energy efficiency standards set out in column 2 of the table to this section apply to room air conditioners described in column 1 that are manufactured during the periods set out in column 3.

Testing standard

(2) A room air conditioner complies with the energy efficiency standard if it meets the standard in the following circumstances:

- (a) if it was manufactured before June 1, 2014, when it is tested in accordance with testing procedures established by CSA C368.1 that are applicable to a room air conditioner as defined in section 108; or

- (b) if it is manufactured on or after June 1, 2014, when the CEER is calculated in accordance with subsection (3).

Calculation of CEER

(3) In respect of a room air conditioner that is manufactured on or after June 1, 2014, compliance with the energy efficiency standard is to be determined by calculating the CEER in accordance with one of the following formulae:

- (a) if the product has standby mode or off mode, but not both, the CEER must be calculated as follows:

CEER = (3 412 × A × 750) ⁄ (B × 750 + C × 5 115)

where

A is the product’s cooling capacity, expressed in kilowatts, derived by testing the product in accordance with testing procedures established by CSA C368.1 that are applicable to a room air conditioner as defined in section 108,

B is the product’s on mode power, expressed in watts, derived by testing the product in accordance with testing procedures established by CSA C368.1 that are applicable to a room air conditioner as defined in section 108, and

C is the product’s standby mode power or off mode power, as applicable, expressed in watts, derived by testing the product in accordance with testing procedures established by CSA C62301 that are applicable to a room air conditioner as defined in section 108; or

- (b) if the product has both standby mode and off mode, the CEER must be calculated as follows:

CEER = (3 412 × A × 750) ⁄ (B × 750 + C × 2 557.5 + D × 2 557.5)

where

A is the product’s cooling capacity, expressed in kilowatts, derived by testing the product in accordance with testing procedures established by CSA C368.1 that are applicable to a room air conditioner as defined in section 108,

B is the product’s on mode power, expressed in watts, derived by testing the product in accordance with testing procedures established by CSA C368.1 that are applicable to a room air conditioner as defined in section 108,

C is the product’s standby mode power, expressed in watts, derived by testing the product in accordance with testing procedures established by CSA C62301 that are applicable to a room air conditioner as defined in section 108, and

D is the product’s off mode power, expressed in watts, derived by testing the product in accordance with testing procedures established by CSA C62301 that are applicable to a room air conditioner as defined in section 108.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

|---|---|---|---|

1 |

Room air conditioners |

CSA C368.1, Table 2, second column |

On or after February 3, 1995 and before June 1, 2014 |

2 |

Room air conditioners that are louvred without reverse cycle |

|

On or after June 1, 2014 |

3 |

Room air conditioners that are louvred with reverse cycle |

|

On or after June 1, 2014 |

4 |

Room air conditioners that are non-louvred without reverse cycle |

|

On or after June 1, 2014 |

5 |

Room air conditioners that are non-louvered with reverse cycle |

|

On or after June 1, 2014 |

6 |

Room air conditioners that are casement-only |

CEER ≥ 9.5 |

On or after June 1, 2014 |

7 |

Room air conditioners that are casement-slider |

CEER ≥ 10.4 |

On or after June 1, 2014 |

- Information

- 113 For the purpose of subsection 5(1) of the Act, the information set out in column 3 of the table to this section must be collected in accordance with the standard or provision set out in column 2 and provided to the Minister in respect of a room air conditioner described in column 1.

TABLE

| Item |

Column 1 |

Column 2 |

Column 3 |

|---|---|---|---|

1 |

Room air conditioners manufactured before June 1, 2014 |

CSA C368.1, for information set out in paragraphs (b) to (d) |

|

2 |

Room air conditioners manufactured on or after June 1, 2014 |

CSA 368.1, for information set out in paragraph (b) Subsection 112(3) of these Regulations, for information set out in paragraph (c) |

|

- Form of labelling

- 114 A room air conditioner must be labelled

- (a) if it was manufactured before June 1, 2014, in the form set out in Schedule 2; or

- (b) if it is manufactured on or after June 1, 2014, in the form set out in Schedule 3.

Manner of labelling

115 The label must either be displayed on the principal display panel of the product’s package or must be one of the following:

- (a) an adhesive tag that meets the requirements of section 14 and that is attached to the product or the principal display panel of its package;

- (b) a flap tag that meets the requirements of section 14 and that is attached to the product; or

- (c) a hang tag that meets the requirements of section 15 and that is attached to the product.

SUBDIVISION B

Large Air Conditioners

Definitions

116 The following definitions apply in this Subdivision.

AHRI 340/360 means the AHRI standard ANSI/AHRI 340/360-2007 entitled Performance Rating of Commercial and Industrial Unitary Air-Conditioning and Heat Pump Equipment. (AHRI 340/360)

IEER means the integrated energy efficiency ratio, expressed in British thermal units per watt hour, that constitutes a single number cooling part-load efficiency metric of a large air conditioner. (IEER)

large air conditioner means a commercial or industrial unitary air conditioner with a cooling capacity of at least 19 kW (65,000 Btu/h) but less than 223 kW (760,000 Btu/h). It does not include a single package vertical air conditioner. (climatiseur de grande puissance)

Energy-using product

117 (1) A large air conditioner is prescribed as an energy-using product.

Limits

(2) However, for the purposes of sections 4, 5 and 118, a large air conditioner is not considered to be an energy-using product unless

- (a) in the case of a large air conditioner with a cooling capacity of less than 70 kW, it is manufactured on or after December 31, 1998; and

- (b) in the case of a large air conditioner with a cooling capacity of 70 kW or more, it is manufactured on or after January 1, 2010.

Energy efficiency standards — cooled by air

118 (1) The energy efficiency standards set out in column 3 of Table 1 to this section apply to large air conditioners that are cooled by air and described in column 1 and that are manufactured during the period set out in column 4.

Energy efficiency standards — cooled by water or evaporation

(2) The energy efficiency standards set out in column 3 of Table 2 to this section apply to large air conditioners that are cooled by water or evaporation and described in column 1 and that are manufactured during the period set out in column 4.

Testing standard

(3) A large air conditioner complies with the energy efficiency standard set out in column 3 if it meets that standard when tested in accordance with testing procedures established by the standard set out in column 2 that are applicable to a large air conditioner as defined in section 116.

TABLE 1

| Item |

Column 1 |

Column 2 |

Column 3 |

Column 4 |

|---|---|---|---|---|

1 |

Large air conditioners that have a cooling capacity of ≥ 19 kW and < 40 kW and either without a heating section or with an electric heating section |

CSA C746-98 |

Energy efficiency ratio ≥ 10.3 |

On or after December 31, 1998 and before January 1, 2010 |

2 |

Large air conditioners that have a cooling capacity of ≥ 19 kW and < 40 kW and either without a heating section or with an electric heating section |

CSA C746-06 for energy efficiency ratio AHRI 340/360 for IEER |

Energy efficiency ratio ≥ 11.2 IEER ≥ 11.4 |

On or after January 1, 2010 |

3 |

Large air conditioners that have a cooling capacity of ≥ 40 kW and < 70 kW and either without a heating section or with an electric heating section |

CSA C746-98 |

Energy efficiency ratio ≥ 9.7 |

On or after December 31, 1998 and before January 1, 2010 |

4 |